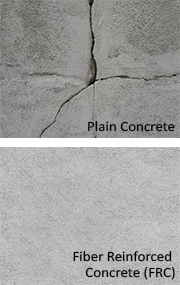

Cracks form as a result of excessive tensile stresses. Cracks initiate from points where stresses change rapidly (stress concentration points, or stress risers), and will continue to migrate over time and with added stress. Weather conditions can also have an impact on the cracking mechanism.

Concrete is strong in compression but weak in tension and flexure. The tensile strength in plain concrete is only about 10% of its compressive strength, so it is primarily ignored in many engineering calculations such as in reinforced concrete (RC) where only the contribution of steel reinforcement is taken into account. Understanding that after the concrete cracks, the reinforcing bars hold the crack together, and transfer load through their anchorage and bond action.

Fiber Reinforcement also works in a similar manner; however, the Fibers provide proactive as well as reactive value. The Fibers significantly reduce the uncontrollable crack openings, transfer load, and work to actually increase the tensile strength.

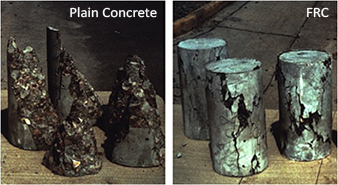

Fibers can slightly increase the compressive strength, but their main impact is on the mode of failure. Plain (unreinforced) concrete will go under brittle (sudden) failure.

The integrity of the concrete will only be maintained if Fibers are added, creating a more ductile product at failure.

Fibers provide a level of internal confinement during compression failure as the internal cracks are held together. This energy absorption (or ductility) is especially valuable and significant when the structure is undergoing seismic,impact, fatigue or explosive loading.

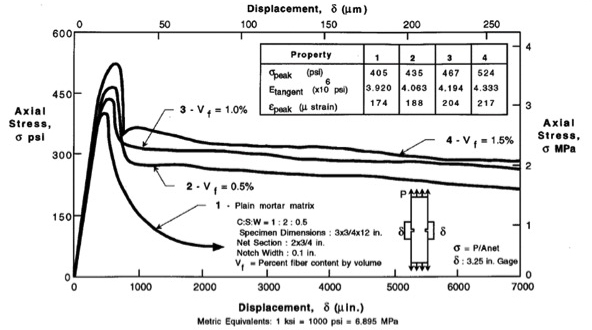

Fibers can increase both the tensile strength and tensile toughness when used at sufficiently high-volume fractions.

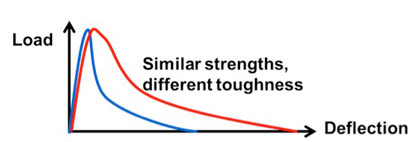

The main effect of fibers in the tensile response is in increasing the toughness as they change the mode of failure from a brittle fracture to ductile behavior.

Toughness is a measure of the material’s ability to absorb energy; it’s a measure of the ductility of the material. One common way of characterizing flexural toughness is by measuring the area under a load deflection curve for a beam specimen. Flexural strength increases with Fiber content; however, the main influence is on the flexural toughness.

Fiber pull-out is one of the predominant sources of toughening mechanisms.

First the fiber resists the pullout force much like a nail being pulled from a piece of wood. Once the peak load is reached, fiber is held by its anchors or by friction, and dissipates more energy as it is slowly being pulled out.

The pullout strength depends on various parameters such as the type of bond, fiber friction, anchorage, ends or roughness.

Depending on the fiber type and surface conditions, the bond may be chemical (adhesion), mechanical, or frictional. Think of a cork screw that penetrates a cork through mechanical anchsorage to provide enough pull force to overcome the friction between the cork and bottle.

A frictional bond is observed as the matrix shrinks and normal frictional forces occur to prevent fiber pullout.

The shape of the fiber anchorage (such as crimping) helps with mechanical bond.

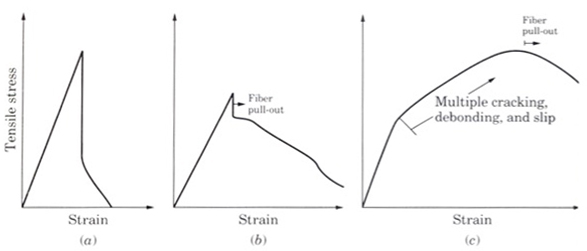

Figure (a) shows low fiber content FRC with little toughening, as the concrete cracks, only a small amount of load can be carried.

Figure (b) shows intermediate fiber content, with some energy absorption due to fiber pull-out (creating a softening curve).

Figure (c) shows high fiber content, with a large amount of energy absorption due to multiple cracking (creating a hardening curve).

Depending on the type, length, properties, and content of Fibers, the tensile (or flexural) response of FRC may vary.