Monahan Filaments, LLC, dba Monahan FiberWorx, is a technology driven developer, manufacturer and marketer of synthetic fibers for reinforcement. Monahan has been producing innovative fibrous materials since 1974; covering a myriad of applications. Monahan continues to be recognized for its strong technical expertise with engineered resins and processes, as well as its superior customer service and industry leadership.

The exclusive focus and Mission of FiberWorx:

In other words: We help improve the quality and performance of concrete.

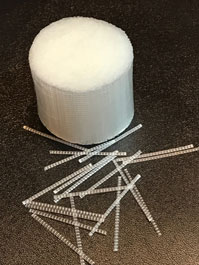

General Products Overview

FiberWorx manufactures and distributes a complete line of synthetic fibers for use as reinforcement in cementicious materials; across many different markets and applications. All manufacturing is in compliance with building codes and ASTM C-1116 Standard Specification for fiber reinforced concrete and shotcrete.

Products:

Typical Applications

- Residential and Industrial Slabs on Grade

- Precast Concrete Products

- Coatings, Overlays and White Toppings

- Elevated Slabs and Structures

- Architectural and Lightweight Concrete

- Exposed Aggregate, Colored and Stamped

- Shotcrete and Sprayed Applications

- Stucco and Plastered Cement

Impact of FiberWorx Fibers in Concrete

Preventing & Managing Cracking Issues

- Effectively prevent and reduce the cracking mechanism in all phases of the concrete's life cycle

- Fibers proactively intersect the uncontrollable crack openings; stop them from propagating while absorbing the cracking energy. As force is applied, the Fibers help to transfer that load through bridging, bonding and pull-out. This process increases the concrete's toughness and residual strength—changing the failure mode (of any SOG or Precast Product) from brittle to ductile.

Alternative / Replacement for Steel Reinforcement

- Independent testing provides sufficient data demonstrating that the use of 3-dimensional fiber reinforcement provides better crack management and control than WWR

- The subject data also provides for the replacement of WWR and steel bars when used as secondary reinforcement, when the steel reinforcement ratio is =/< 0.2%

Safer and Easy to Use

- No storage, handling or placing of steel reinforcement—all fiber reinforcement is “built-In” and is always, and automatically positioned properly, when mixed according to ASTM C-94

- Avoid tripping and dangers from handling rusty steel bars, wire rolls or mats

Financial and Sustainable Gains

- Eliminates the need for purchasing, storing, handling, cutting and bending of secondary steel reinforcement

- Enjoy a significant cost advantage over the purchase and management of steel reinforcement; Reduces the total time on the job—flowing directly to the bottom-line profit of your project

- Drastically reduces “call-backs” due to cracking in Ready Mix C.O.D. business

There are many more benefits related to the use of FiberWorx Fibers. Please contact your FiberWorx representative for more information, or to discuss your specific application!